Table of Contents

- TL;DR

- Why Do Electricians Wear Rubber Soled Boots?

- What Are Rubber Soled Boots?

- Benefits Of Rubber Soled Boots

- What Does It Mean For Boots To Be Electrical Hazard Rated?

- Is It True That Electricians Wear Rubber Boots?

- Do Electricians Wear Steel Toe Boots

- What Are The Risks Of Steel Toe Shoes For Electricians?

- What Does OSHA Say About Steel Toes For Electricians?

- Is Composite Toe Better Than Steel Toe For Electricians?

- Boot Features Electricians should Look For

- Protective Toe Cap Or Steel Toe Cap Design

- Non-Slip Outsole And Ankle Support

- Electrical Hazard Rating System

- Maintenance And Care Of Rubber Soled Boots

- What Are The Best Brands For Rubber Soled Electrician Boots?

- FAQs

TL;DR: Rubber-soled boots are crucial for electricians, offering safety, protection, and comfort. Key features to consider include comfort, durability, non-slip grip, ankle support, abrasion-resistant toe cap, and electrical hazard rating. Choose between soft and safety toe designs based on job requirements and consider brands like Timberland, Wolverine, Thorogood, and others. Proper maintenance and care will prolong the life of your boots, ensuring continued protection on the job.

Why Do Electricians Wear Rubber Soled Boots?

Electricians wear rubber-soled boots to protect themselves from electrical hazards. Rubber is a good insulator that prevents electricians from being grounded and getting injured when in contact with live wires.

If they were to accidentally come into contact with a live wire, the rubber soles of their boots prevent the flow of electricity through their body and into the ground. Essentially the electrician would not be grounded whereas if the boot soles were made with a conductive material the electrician would be grounded and would then be injured. If their boots were not rubber-soled the electrician would be at serious risk of electrical shock, which would possibly lead to serious injury or worse.

The thickness of the rubber soles does make a difference. Thicker boot soles provide better insulation and protection against electrical shocks. With that being said it is always important to make sure the boots are in proper working condition and do not have any compromising damage that may affect their safety.

While rubber-soled boots are an essential PPE item and safety measure, they are no guarantee against electrical shock. It is always crucial to use other proper safety measures and PPE, such as insulated tools and working with a partner when possible, to minimize the risks of electrical shock and overall day-to-day dangers.

As someone who has sold boots for many years, I can confidently say that rubber-soled boots are a necessary safety item for electricians to prevent electrical shock. They provide insulation and protection while also offering comfort, cushioning, and traction on the job site.

What Are Rubber Soled Boots?

Rubber-soled boots are a type of protective footwear designed to protect the wearer from electric current, that have a rubber sole on the bottom. They’re also known as electrical grade safety boots, or EGSB for short. Electricians are at a high risk of electric shock in their day to day, rubber soled boots prevent themselves from being grounded and therefore prevent injury from an electric current. In essence, rubber is a great insulator, so it helps keep the electrician safe when dealing with live wires.

The primary purpose of rubber soled shoes is to provide protection against accidental contact with open circuits that may contain dangerous amounts of current. This is especially important in environments where materials containing metal parts could be exposed to moisture, which can create a risk of shock due to conductive currents running through them. As such, they offer an extra layer of protection by preventing this kind of contact in these potentially hazardous situations.

In addition to their protective qualities, rubber soles are typically very comfortable and durable. They tend to be flexible enough to move freely while providing a good grip on many surfaces – perfect for those who work long hours on their feet! For all these reasons, rubber-soled boots are popular among professional tradesmen like electricians who need reliable and effective foot protection against electrical hazards in their line of work.

What are the Best work boots for electricians

Choosing the best workwear including shoes is a difficult decision, especially for electricians because you’re wearing them all day every day. You’ll want to consider weight, durability, comfort, and of course price. Personally, my favorite work boot for electricians is the Timberland Helix lace-up boot. It is waterproof, extremely comfortable, durable, and lighter weight than most.

I have created a full list of the top-rated footwear for any electrical tradesperson if you’re looking for a more detailed breakdown of work boots.

Benefits Of Rubber Soled Boots

- Protection against electrical shock

- Slip-resistant properties

- High level of protection rating

- Non-conductive

- Provides insulation against electrical current

- Offers superior comfort

- Enhanced grip on slick surfaces

- Absorbs shocks from uneven terrain or slippery conditions

- Ideal for those exposed to extreme weather conditions

The benefits of a rubber sole boot are hard to ignore when it comes to electricians. The protection offered by the rubber soles is invaluable for not only protecting against electrical shock, but they also help prevent slipping. When you’re working near things so dangerous like an electrical circuit that could cause serious injury anything that aids in electrical safety is a beneficial. Not only do rubber soled boots provide excellent insulation from electricity and other external hazards, they also have several additional advantages.

One such advantage is the high level of protection rating provided by many standard steel toe rubber-soled boots. This rating indicates the amount of voltage resistance the boot has been tested for, usually up to 1000V which provides plenty of coverage for most low voltage situations encountered in modern work environments. In addition, since rubber soles are non conductive they can help protect against accidental contact with live electrical currents making them ideal footwear choice for those working around electricity.

Another benefit of having a pair of rubber-soled boots is their slip resistance properties. Rubber offers more traction than leather due to its higher coefficient of friction providing better grip when walking on slick surfaces like oil, water or snow helping reduce the risk of slips and falls while performing essential tasks. Additionally, the flexibility and cushioning effect created by the air pocket between your foot and ground helps absorb any shocks you may encounter while navigating uneven terrain or slippery conditions.

A decent pair of rubber soled boots offer superior comfort along with top notch safety features ensuring workers don’t have to sacrifice one over another. Their ability to insulate against electrical current combined with enhanced grip makes them perfect for anyone who works near potentially hazardous equipment as well as those exposed to extreme weather conditions where good foot support is paramount

What Does It Mean For Boots To Be Electrical Hazard Rated?

When a boot receives an electrical hazard (EH) rating, it means that the boot has undergone rigorous testing and design to provide a level of protection against electrical hazards.

The EH rating is a measure of the boot’s sole and heel capability to resist up to 18,000 volts of electrical current for a minute without allowing the current to conduct through to the ground. This rating is vital in reducing the likelihood of electric shock, electrocution, and other electrical hazards for workers who may come into contact with live wires or other electrical sources while working. It’s worth noting that EH rated boots don’t provide complete protection against all electrical hazards, but they do provide an extra layer of protection to workers in specific situations.

The American Society for Testing Materials (ASTM) has specific standards for these types of shoes. All ASTM-rated footwear will be clearly labeled with its rating – either “EH” for electrical hazard or “SD” for static dissipating. Additionally, all EH rated boots should meet NFPA 70E requirements as well as OSHA regulations; this makes sure that you get maximum protection from any potential accidents or incidents related to electricity on the worksite.

No matter what type of environment you work in – whether indoors or outdoors – make sure you invest in quality protective gear like EH rated work boots to stay safe at all times. It’s worth spending the money upfront because not only does it ensure your safety but it also saves time and money down the road if an accident were to happen!

Is It True That Electricians Wear Rubber Boots?

It’s true that electricians wear rubber boots in some cases but in most cases electricians wear leather work boots. Rubber boots are one way to keep your feet dry when around water, to stay safe when working with electricity, and can be especially helpful when trying to maintain adequate protection when you need footwear with little to no electrical conductivity.

With that said rubber boots are not a requirement for electricians and the vast majority use rubber soled boots instead of rubber boots because they’re more comfortable, durable, breathable, and overall just last longer.

Rubber soles also tend to be more comfortable for those who do extensive amounts of walking, standing, climbing ladders or stairs, or just generally moving throughout their day making them an ideal choice for electricians. In addition to providing protection from shocks, rubber soled boots provide extra cushioning which helps reduce fatigue over long periods of time.

There are different types of protective equipment used by electricians depending on their work environment and other factors. For example, composite safety toe shoes are often worn when working in hazardous environments where there is a risk of falling objects or machinery malfunctions. Non-conductive footwear must also be worn around live electrical wires as it prevents electricity from passing through the body if an accident occurs. It’s important for electricians to make sure they always have the right type of protective gear before beginning any task involving electrical current.

Do Electricians Wear Steel Toe Boots

Yes, electricians wear safety footwear including steel toes.

Electricians need protection from static electricity and other shock-related hazards while they’re on the job. Steel toe boots are rubber-soled which is known for their insulating properties, which help to protect workers when dealing with high voltage components.

With that said there are some precautions you to keep in mind. Steel toe boots do provide outstanding compression protection against foot injuries in cases where something heavy were to fall onto the toe area. However, steel is a great conductor of electricity so it’s critical to make sure no part of the steel toe cap is exposed to wires or terminals.

It may also be attractive to look for composite toe boots. Composite toes are made from a combination of nonconductive materials and would be a great choice for electricians.

In summary, if electricians opt for steel toe boots, they should ensure that all metal components are covered by insulated materials like rubber or leather before approaching any live equipment. This will reduce the risk of electrical shock and allow welders to stay safe while protecting their feet at the same time.

What Are The Risks Of Steel Toe Shoes For Electricians?

When it comes to the workplace, electricians have unique safety needs in comparison to other professions. Electricians need work boots that are insulated against electricity, provide slip resistance, are durable to daily walking, crouching, ladders, stairs, and also need to be comfy.

Steel toe shoes may seem like they’d meet these criteria and in almost all cases they do. Unfortunately as you wear your boots things happen. They get damaged, cut, punctured, worn down, etc. If steel toes are compromised they can become a safety hazard and will need to be replaced. For example if your steel toe cap were to become exposed through wear or was cut and your foot was to be in contact with the steel toe cap, there would be a heightened risk of electrocution.

Over the years I’ve reommended avoiding the situation at all by wearing composite toe boots instead of steel toe.These types of boots provide the same level of comfort and but with an added extra bit of safety. Their soles are made from materials such as rubber, the same as steel toes, which resist conductive heat and keep feet safe from electrical shocks even if exposed to wet conditions or extreme temperatures but are also 30% lighter than their steel-toe counterparts.

It’s important that electricians take into consideration the potential risks associated with wearing steel-toe shoes on the job site before investing in a pair of work boots. With so many options available today, there’s no reason why anyone should compromise their safety by choosing a style without proper electrical resistance and foot protection features built right in!

What Does OSHA Say About Steel Toes For Electricians?

OSHA has even provided direct guidance for electricians and steel-toe boots:

Is Composite Toe Better Than Steel Toe For Electricians?

Yes, composite toes are better than steel toes for electricians. Composite toes are nonconductive inherently and therefore add a degree of safety that steel toes cannot, even though it is a small amount of extra protection.

Boot Features Electricians should Look For

Some features electricians should look for when looking for new boots include:

Comfort – Make sure the boots are comfortable, this would include the insole, proper width (work boots usually come in both regular and wides), and instep room (top of your foot)

Durability – Rubber soles tend to be very durable, other than the soles themselves make sure the boots are made with either genuine leather or a good fabric. Avoid fake leather at all costs.

Non Slip Grip – Rubber sole boots are slip resistant already but some boots are made to be more slip resistant than others. Depending on your working conditions you may want to check reviews on slip resitance.

Ankle Support – Electricians are often climbing ladders, stairs, doing a lot of walking and crouching so it is critical your boots provide adquate ankle support to prevent injury

Abrasion Resistant Toe Cap – If you find yourself rubbing the leather down on your work boot in the toe area you may look for a boot with an abrasion resistant toe cap. This would help prevent exposure of the toe cap and extend the life of the boots.

Electrical Hazard Rated (EH) – Most boots are electrical hazard rated but it is vital for electricians to make sure their boot are indeed EH rated. There is usually indications on the box or on the website that the boots are EH rated. You can also look on the tongue of the boot for “EH” which would confirm they are properly rated.

Electricity has no room for error and being prepared should always be at the top of any electrician’s priority list. Wearing quality rubber soled boots will ensure you stay safe on the job while providing comfort and durability so you can focus on what matters most—getting the job done right!

Protective Toe Cap Or Steel Toe Cap Design

It’s no secret why electricians wear rubber soled boots: they need adequate protection. But what kind of protection? Well, that depends on the job you’re doing and the environment in which you are working.

Soft toe Pros:

- Lightweight

- Can be more comfortable if you have wide feet and tend to rub the sides of the steel toe cap

Soft Toe Cons:

- Does not protect against falling objects

- Employers may require safety toe caps

Safety Toe Pros:

- Can protect against falling objects

- Employers often require safety toe boots

Safety Toe Cons:

Heavier than nonsafety toe boots

Most safety toe boots will also come in nonsafety toe versions. Meaning you get the same slip resistance, ankle support, and waterproofing (when applicable) as safety toe boots but no protection against heavy falling or rolling objects. Also, employers often require safety toe boots which might mean you’d have to purchase safety toe boots anyway.

Non-Slip Outsole And Ankle Support

Slip resistance is another aspect of on the job safety many don’t think about until they’re face up looking at the sky becuase they slipped and fell. Most rubber soled boots are slip resistant, at least the safety toe boot versions. This means that you shouldn’t slip as much on ice, oil, water, or other wet surfaces. It is important to make sure your boots are slip resistant, to do so it will often be marked on the boot box or website you’re purchasing from that they are slip resistant. You can also check the sole of the boot, it is often enscribed on the soles that the boots are slip resistant. Another option is to look on the boot tongue for “SR” or “slip resistant.”

When looking for ankle support pull on or lace up boots offer the most ankle support. How much support you need is up to you, I prefer pull on boots as they’re easier on and off, and I don’t have to worry about laces coming undone. Lace-ups do tend to provide the best ankle support, unsurprisingly, as you can tighten them up. Overall it is up to you to choose what is best for your feet.

Electrical Hazard Rating System

Electricians work around a high flow of electricity, so proper precautions are of the highest priority. This is why electricians wear rubber-soled boots or rubber-soled shoes to protect themselves from the dangers of working in an electrical environment. Rubber soles provide a great level of protection against electric shock and other potential hazards that can occur when working around live wires.

Boots for electricians are essential not only because they offer superior protection but also because they help ensure that workers remain properly insulated from any sources of electricity present at the job site. By taking the necessary steps to select appropriate protective footwear, one can help ensure that his or her feet remain safe even in environments where there is a higher than usual flow of electricity.

Maintenance And Care Of Rubber Soled Boots

Maintaining rubber-soled boots is no different than any other work boot. You’ll want to use leather conditioner periodically, I recommend once a month if you’re not around much water and twice a month if your rubber-soled boots get wet frequently.

You may want to use a waterproofing product for added water protection, my favorite is sno-seal because it not only waterproofs your boots but also conditions them as well. Another aspect you may want to consider is a toe guard if you find yourself dragging your boots across concrete when crouched. This is the most common cause of the steel toe being exposed, a toe guard such as tuff-toe is, in my opinion, the best way to protect your safety toe boots.

Another aspect of maintaining your industrial safety footwear is the insoles. Finding a good insole is tough but it can be the difference between you loving or hating the boots. I recommend using the Timberland Anti-Fatigue insole because it is the thickest and provides the most comfort out of all of the industrial safety footwear insoles I’ve tested.

What Are The Best Brands For Rubber Soled Electrician Boots?

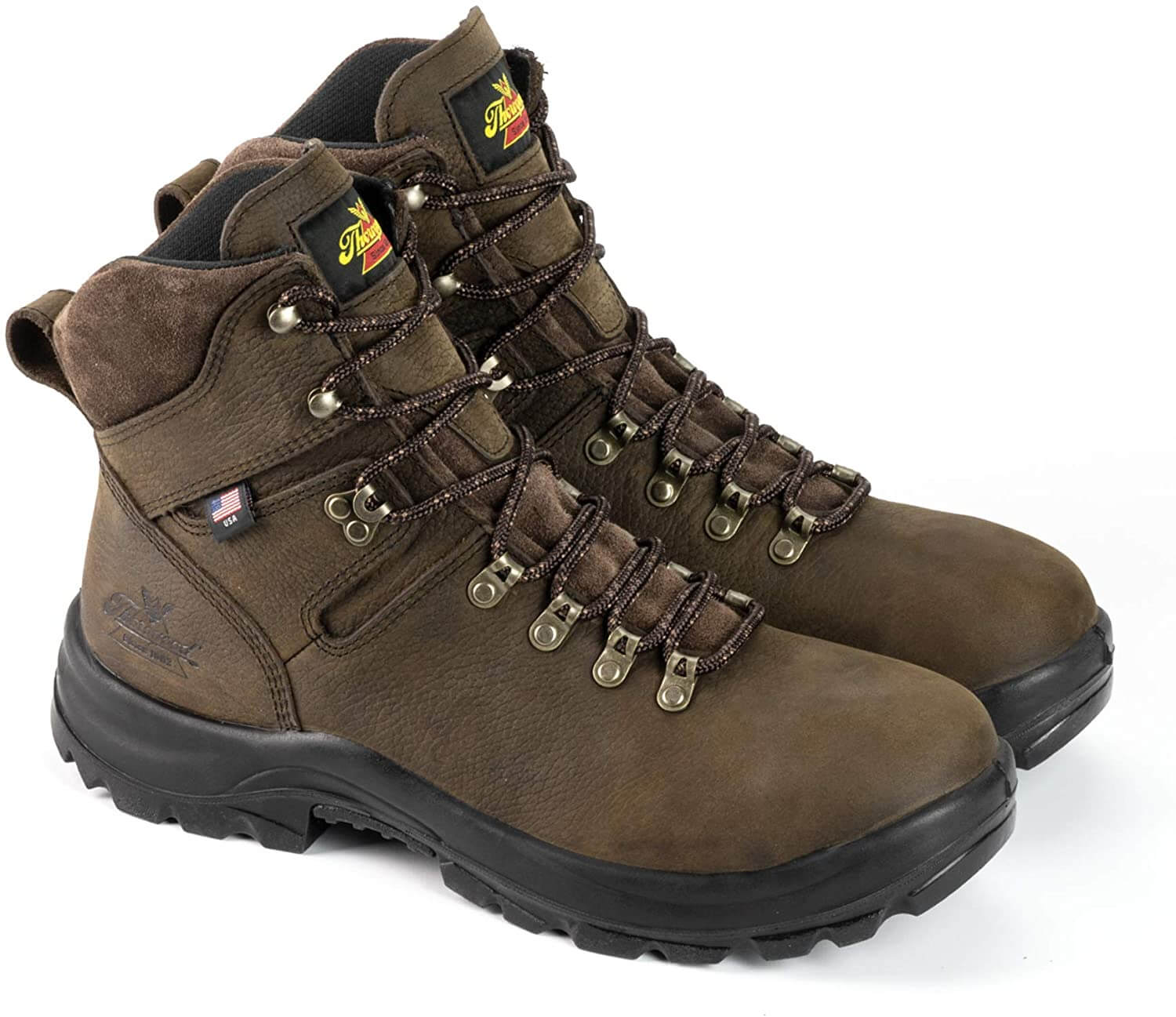

My preferred rubber-soled boots for electricians include:

- Timberland

- Wolverine

- Thorogood

- Twisted X

- Ariat

- Double H

- Justin

- Cat

- Carhartt

There are obviously more brands out there that make great electrician boots but these are a few to start with.

FAQs

Are Rubber Soled Boots Comfortable To Wear?

Yes, rubber-soled boots are comfortable to wear. In some cases you will want to replace the insole that comes with the boots to increase the comfort although this is not required for the boots to be comfortable. The most important aspect, in my opinion, to comfortable work boots is to get the right fit. Most boots come in both regular (D) and wide (EE) widths. Getting the right fit is the most important part of boot comfort.

Are Rubber Soled Boots Waterproof?

Not all rubber soled boots are waterproof. Many of them come waterproof, thanks to a waterproof liner, or can be made waterproof if they are a full grain leather. It is always important to check whether your rubber-soled boots or rubber soled shoes come waterproof prior to purchasing.

Are Rubber Soled Boots Breathable?

Rubber soled shoes and rubber soled boots can be breatheable but it will depend on the boot itself. Keep in mind the boots that come waterproof are made waterproof through a liner that goes between the exterior and interior of the boots. There will often be a fabric liner on the inside of the boots and just beneth that fabric is the waterproof liner. If your boots have this liner they are going to be much less breatheable, and often times more hot.

Are Rubber Soled Boots Expensive?

Are rubber soled boots expensive? This is a great question to ask when deciding which work boot to buy. After all, the last thing you want is to invest in something that doesn’t offer long-term value. So, how much do these specialized boots cost?

Well, it depends on what type of rubber sole boots you’re looking for and from where you’re buying them. Some stores might charge more than others; likewise, some manufacturers may have higher quality standards and better materials than their competitors. All this contributes to the price point of the product. Generally speaking though, most good-quality rubber soled boots range anywhere from $80-$300 dollars depending on brand and features included like waterproofing or arch support.

But does paying more always mean getting a better pair of shoes? Not necessarily! It’s important to consider your needs as well – are you looking for lightweight protection? Or perhaps durability and extra cushioning? Once you know exactly what kind of rubber sole boots will best suit you and your job requirements, then it’s easier to narrow down which brands will fit within your budget without sacrificing any key features.

So if you want top-of-the-line rubber soled boots with maximum comfort at an affordable price tag – make sure to do your research before making any purchases! Knowing what options exist out there can help save time and money while still allowing you get the perfect boot for whatever task awaits.

Are Rubber Soled Boots Breathable?

Rubber soled shoes and rubber soled boots can be breatheable but it will depend on the boot itself. Keep in mind the boots that come waterproof are made waterproof through a liner that goes between the exterior and interior of the boots. There will often be a fabric liner on the inside of the boots and just beneth that fabric is the waterproof liner. If your boots have this liner they are going to be much less breatheable, and often times more hot.

Conclusion

In conclusion, rubber-soled boots are essential for electricians due to their safety, protection, and comfort features. The right pair of boots can make all the difference when working around electricity. Some key features to look for include comfort, durability, non-slip grip, ankle support, abrasion-resistant toe cap, and electrical hazard rating. Choosing between soft toe and safety toe designs will depend on the specific job requirements and work environment.

Additionally, ensuring that your boots have a non-slip outsole and adequate ankle support is crucial for overall safety. Proper maintenance and care of your rubber-soled boots will extend their lifespan and ensure that they continue to provide the necessary protection.

Some of the top brands for rubber-soled boots include Timberland, Wolverine, Thorogood, Twisted X, Ariat, Double H, Justin, Cat, and Carhartt. Investing in a quality pair of rubber-soled boots is a smart choice for any electrician, providing protection, comfort, and peace of mind while on the job.