How your work boots are constructed has a major impact on their longevity. Ideally, all boots would last for years and years but unfortunately, they don’t. That is why it is important you know what you’re looking at when purchasing boots and how to determine which is right for you. One aspect of boot construction is the welts. Boot welting can come in many different variations such as the Goodyear welt, Blake Stitch, and cement construction.

It can take time to decide between the Goodyear welt, the Blake stitch, and cement construction for shoes. So which is the best construction type for your shoes? In this blog, we’ll explore the different types of shoe construction and discuss the advantages of each. Then we’ll recommend a shoe construction type that is the best for you!

Quick Conclusion: Goodyear Welted boots are the best between Blake Stitch and cement constructed boots due to their durability, water resistance, and repairability. Although Blake Stitch offers style and cement constructed boots are budget-friendly, neither can match the longevity and reliability of Goodyear Welted boots. Ideal for demanding work environments, these boots provide a wise investment, blending quality craftsmanship and top-notch performance.

As a work boot salesman with years of experience, I’ve seen firsthand the negative consequences of customers not fully understanding the differences between boot construction styles, particularly when it comes to purchasing boots online. It’s not uncommon for customers to be swayed by attractive product images or positive reviews, only to later realize that the boots they chose are not a good fit for their job or work environment.

One customer I worked with purchased a pair of boots online that looked sturdy and durable, with a price point that seemed reasonable. However, when he received the boots and started wearing them on the job, he quickly realized that they were not suitable for his work environment. The boots had a cement construction, which made them lightweight and affordable, but also less durable and not ideal for heavy-duty work.

Similarly, another customer purchased a pair of boots with a Blake stitch construction, thinking that they would be durable enough for his job as a landscaper. However, after just a few weeks of wear, the boots started to fall apart and didn’t hold up to the demands of his job.

Knowing why you’re looking for or what type of boot will work best for your job is critical to getting the most bang for your buck. I’ve tried to distill the most important aspects of each boot construction style below in an effort to help you make the best decision the next time you’re looking for new work boots.

Goodyear Welt Vs. Blake Stitch Vs. Cement

When it comes to Goodyear welts, Blake stitch, and Cement, which is the best? The answer is all three, in different ways. First, we should explore what each of these types of boot construction actually is.

What is a Goodyear Welt for Work Boots?

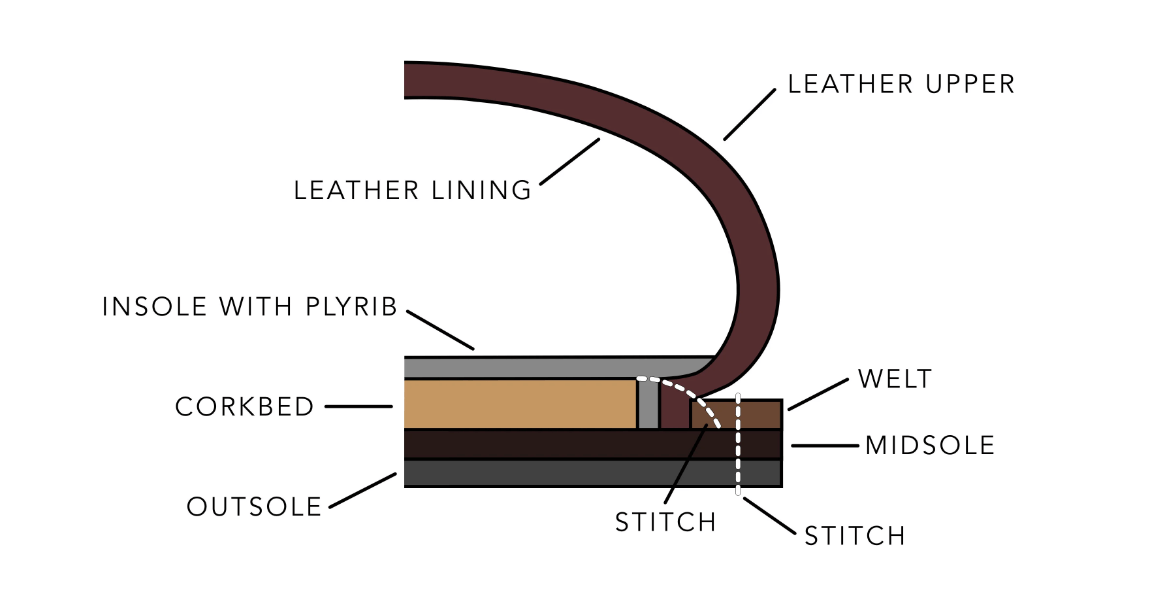

In the realm of boots, the Goodyear Welt stands tall as a distinguished construction technique. Employing this method, a strip of material, typically leather or rubber, is stitched around the boot’s perimeter.

This strip, the welt, is then attached to both the upper and the insole. A sturdy bond emerges, a testament to skilled craftsmanship.

Between the insole and the outsole, a cavity materializes, which is subsequently filled with cork or foam. This addition serves to bolster comfort and support.

Finally, the outsole joins the party, affixed securely to the welt. Result? A boot exuding quality, comfort, and resilience.

In essence, the Goodyear Welt is a complex dance of materials, melding together to form a durable, long-lasting, and reliable boot.

Pros and Cons of Goodyear Welted Work Boots

Pros:

Durability: Goodyear Welted boots are known for their exceptional durability due to the robust stitching that connects the upper, insole, and outsole. This strong bond ensures the boots can withstand heavy use and harsh work environments.

Water Resistance: The strip of leather that runs along the edge of the outsole in Goodyear Welted boots acts as a barrier, preventing water from seeping through the seams and into the boot. This makes them an ideal choice for individuals working in wet or muddy conditions.

Repairability: Goodyear Welted boots can be easily resoled or repaired, extending their lifespan significantly. When the outsole wears down, it can be replaced without damaging the rest of the boot, making it a long-lasting investment for workers who rely on their boots daily.

Support and Comfort: The construction process of Goodyear Welted boots includes a cavity between the insole and the outsole, which is typically filled with cork or foam. This addition provides extra cushioning and support for the wearer, contributing to overall comfort.

Better Craftsmanship: Goodyear Welted boots generally exhibit a higher level of craftsmanship due to the complex stitching process and the use of more durable materials, resulting in a boot that offers better support, comfort, and longevity.

Cons:

Cost: Goodyear Welted boots tend to be more expensive than other types of work boots, such as cement constructed or Blake Stitch boots. The complex construction process, higher-quality materials, and additional labor contribute to the higher price.

Weight: The additional materials and stitching used in Goodyear Welted boots can make them heavier than other types of work boots. This may be a concern for individuals who require lightweight footwear for extended periods of wear.

Break-in Period: Goodyear Welted boots may require a longer break-in period compared to other boot constructions. The sturdy materials and construction can initially feel stiff, and it may take some time for the boots to conform to the wearer’s feet and become more comfortable.

Bulkiness: Goodyear Welted boots can be bulkier than other types of work boots, such as Blake Stitch or cement constructed boots. This may not be suitable for individuals who prefer a sleeker and more streamlined appearance in their work footwear.

What is a Blake Stitch

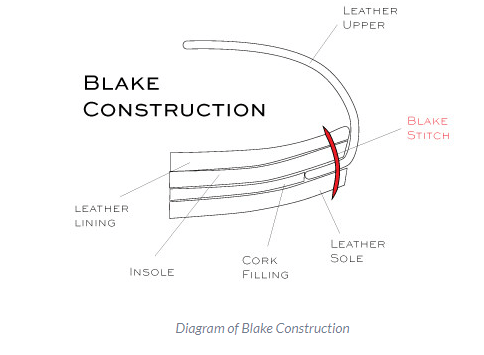

A Blake Stitch boot is a type of footwear construction where the upper is directly stitched to the insole. The outsole is then added, resulting in a lightweight and flexible shoe. Although it lacks the water resistance and easy re-soling of a Goodyear Welt boot, it offers a more refined appearance and is often considered more stylish.

What is a Cement Construction

A budget-friendly option, cement construction involves gluing the upper directly to the outsole. These boots might not stand the test of time like their stitched counterparts. Remember, while cement construction offers some advantages, it may not be as water-resistant, long-lasting, or easily repaired as boots utilizing other methods, such as Goodyear Welt or Blake Stitch.

Cement constructed work boots are a popular choice for those who need lightweight and affordable boots for light to moderate work. This type of boot construction is characterized by a strong adhesive that is used to bond the leather upper, sole, and midsole together, creating a one-piece unit that is both durable and flexible.

In cement constructed work boots, the leather upper is attached to the sole with a strong adhesive, which is then cured to create a permanent bond. The midsole is also attached to the sole in the same way, creating a single unit that is both lightweight and durable. This construction method is often used in athletic shoes as well, due to its lightweight nature.

One of the primary benefits of cement constructed work boots is their affordability. Because this construction method is less labor-intensive than other methods, it allows manufacturers to offer boots at a lower price point. Additionally, cemented sole work boots are typically more flexible and require less break-in time than other methods, making them a popular choice for those who need a comfortable and lightweight boot for light to moderate work.

However, one drawback of cemented sole work boots is that they may not be as durable as other types of work boots. Because the upper is only attached to the sole with adhesive, it may not hold up as well in extreme conditions or heavy use. Additionally, the adhesive used in cement construction may break down over time, which can lead to separation between the upper and sole.

Despite these drawbacks, cement constructed work boots remain a popular choice for those who need an affordable and lightweight boot for light to moderate work. By understanding the benefits and drawbacks of this construction method, you can make an informed decision when choosing the right work boots for your needs.

Goodyear Welts vs Blake Stitch Work Boots

Goodyear Welts and Blake Stitch boots both have their pros and cons but this is a comparison for which is better for work boots.

When comparing Goodyear Welted and Blake Stitch work boots, it’s important to consider the differences in construction, durability, and style that each method offers.

First and foremost, the Goodyear Welted construction technique is synonymous with durability. By stitching a welt, a strip of material, around the boot’s perimeter, it creates a strong bond between the upper, insole, and outsole. This robust connection ensures that the boots can withstand harsh work environments, heavy use, and unfavorable weather conditions. In comparison, Blake Stitch work boots, while flexible and stylish, simply lack the same ruggedness.

Secondly, Goodyear Welted boots offer superior water resistance. The welt acts as a barrier, preventing water from seeping through the seams and into the boot. This makes them a perfect choice for individuals working in wet or muddy conditions. Although Blake Stitch boots have a more refined appearance, their construction leaves them more vulnerable to water intrusion.

Lastly, Goodyear Welted boots boast an ease of repair that is unmatched by their Blake Stitch counterparts. When the outsole of a Goodyear Welted boot eventually wears down, it can be easily replaced, breathing new life into the boot and extending its lifespan significantly. In contrast, repairing a Blake Stitch boot is more complicated and may not always be possible, depending on the specific construction and extent of wear.

In contrast, Blake Stitch boots are characterized by their lightweight and flexible design. The construction involves stitching the upper directly to the insole, and then attaching the outsole. While this method produces a more refined appearance, it lacks the water resistance and easy re-soling capabilities of Goodyear Welted boots. However, Blake Stitch boots are often considered more stylish and versatile in terms of fashion.

In summary, Goodyear Welted work boots are overall better than Blake Stitch work boots. Goodyear welted work boots provide better durability, water resistance, and ease of repair, making them an excellent choice for demanding work environments.

Cement Constructed Boots: Pros and Cons

Cement constructed boots are popular for several reasons, including their affordability, simplicity, and relatively lightweight design. However, they also come with certain drawbacks, such as reduced durability, water resistance, and repairability compared to their stitched counterparts. Let’s dive into the pros and cons of cement constructed boots to understand their popularity and limitations.

Pros of Cement Constructed Boots:

- Affordability: One of the main reasons cement constructed boots are popular is their cost-effectiveness. Since the construction process involves gluing the upper directly to the outsole, fewer materials and labor are required, resulting in lower production costs. This makes them an attractive option for budget-conscious consumers.

- Simplicity: Cement construction is a straightforward process, making it easier and faster to manufacture boots using this method. This simplicity can also contribute to the affordability of these boots.

- Lightweight: Cement constructed boots tend to be lighter than boots made using other methods like Goodyear Welt or Blake Stitch. The absence of stitching and the use of adhesive instead of welts can contribute to the overall reduced weight of the boot, making them more comfortable for extended periods of wear.

Cons of Cement Constructed Boots:

Reduced Durability: One of the main disadvantages of cement constructed boots is their limited durability compared to stitched boots. The adhesive used to bond the upper and outsole can weaken over time, especially under heavy use or exposure to harsh conditions. As a result, these boots may not last as long as their Goodyear Welted or Blake Stitch counterparts.

Lower Water Resistance: Cement constructed boots are not as effective at preventing water intrusion as stitched boots. The absence of a welt or stitched barrier makes it easier for water to seep into the boot, making them less suitable for wet or muddy work environments.

Limited Repairability: Due to their glued construction, cement constructed boots are challenging to repair once the adhesive begins to fail or the outsole wears down. In most cases, replacing the entire boot is the only viable option. This is in contrast to stitched boots, which can often be resoled or repaired, extending their lifespan.

In conclusion, cement constructed boots are popular due to their affordability, simplicity, and lightweight design. However, they come with certain drawbacks, such as reduced durability, water resistance, and limited repairability. Consumers should carefully weigh the pros and cons of cement constructed boots against other construction methods to determine the best option for their needs and work environment.

Which is Better Goodyear Welted Work Boots or Cement Constructed Work Boots

When comparing Goodyear Welted boots and cement constructed boots, several factors come into play, including durability, water resistance, repairability, price, and overall quality. By examining these aspects and providing examples, we can conclude that Goodyear Welted boots are generally superior to cement constructed boots.

Durability: Goodyear Welted boots are renowned for their durability, primarily due to the robust stitching that connects the upper, insole, and outsole. This secure bond ensures the boots can withstand heavy use and harsh work environments. For instance, construction workers, loggers, and miners often prefer Goodyear Welted boots because they provide the necessary support and protection over extended periods. On the other hand, cement constructed boots rely on adhesive to bond the upper and outsole, which can weaken over time, leading to reduced durability especially if you’re around water or other chemicals.

Water Resistance: Goodyear Welted boots offer a superior level of water resistance due to the welt that acts as a barrier, preventing water from entering the boot. This makes them an ideal choice for individuals working in wet conditions, such as fishermen or those in the agriculture industry. Cement-constructed boots, lacking the stitched barrier, are more vulnerable to water seepage, making them less suitable for wet work environments.

Repairability: One of the standout features of Goodyear Welted boots is their ease of repair. When the outsole eventually wears down, it can be replaced without damaging the rest of the boot, thereby extending its lifespan significantly. For instance, a worn-out Goodyear Welted boot can be resoled multiple times, making it a long-lasting investment for workers who rely on their boots daily. Cement constructed boots, however, are challenging to repair once the adhesive fails or the outsole wears down, often necessitating a complete boot replacement.

Overall Quality: Goodyear Welted boots generally exhibit a higher level of craftsmanship and quality compared to cement constructed boots. This is due to the complex stitching process and the use of more durable materials, resulting in a boot that offers better support, comfort, and longevity. As an example, a pair of high-quality Goodyear Welted boots can last for years, if not decades, with proper care and maintenance, while cement-constructed boots may need replacing after just a few years, or even months, of use.

Cons of Cement Constructed Boots:

Reduced Durability: One of the main disadvantages of cement constructed boots is their limited durability compared to stitched boots. The adhesive used to bond the upper and outsole can weaken over time, especially under heavy use or exposure to harsh conditions. As a result, these boots may not last as long as their Goodyear Welted or Blake Stitch counterparts.

Lower Water Resistance: Cement constructed boots are not as effective at preventing water intrusion as stitched boots. The absence of a welt or stitched barrier makes it easier for water to seep into the boot, making them less suitable for wet or muddy work environments.

Limited Repairability: Due to their glued construction, cement constructed boots are challenging to repair once the adhesive begins to fail or the outsole wears down. In most cases, replacing the entire boot is the only viable option. This is in contrast to stitched boots, which can often be resoled or repaired, extending their lifespan.

In conclusion, Goodyear Welted boots are better than cement constructed boots in terms of durability, water resistance, repairability, and overall quality. By providing better protection and longevity, Goodyear Welted boots prove to be a superior investment for individuals in demanding work environments. While cement constructed boots may be more affordable initially, the long-term advantages of Goodyear Welted boots make them a better choice for those seeking a reliable and high-quality work boot.

Pingback: How To Stretch Steel Toe Boots